Assessment & Remediation

-

E&P Groundwater Remediation

Western Colorado Groundwater contamination due to migration from a natural gas well along natural fractures resulted in benzene and methane in surface water and groundwater. After several years of operating a sparge system with little progress, Rule was selected to provide remediation for the site. Our evaluation concluded that the existing system was not effective……

-

Refinery Groundwater Containment System

Wyoming A containment system was designed under a Consent Order with the WDEQ to prevent off-site migration of contaminated groundwater and LNAPL. An alternative evaluation design was used to select a soil bentonite slurry wall with a series of interceptor. Data from a detailed subsurface investigation was used to design a 1,700-foot long by 25-foot……

-

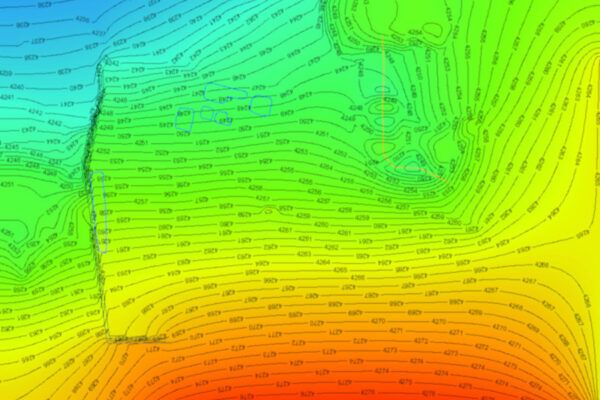

Refinery Groundwater Modeling

Wyoming A groundwater model was developed to address corrective actions under the WDEQ to provide an understanding of remedial alternatives to prevent off-site migration of contaminated groundwater and LNAPL. A three-dimensional finite-difference groundwater model was used to assist with the design and placement of a groundwater interceptor trench. The model utilized detailed subsurface characterization to……

-

E&P Tank Closures

Northwestern Colorado Closures were completed on over 70 produced water holding tanks covering a large area in a remote part of northwestern Colorado. The replacement of the existing culvert pit holding tanks was coordinated with the oil and gas operator to install above-ground tanks with minimal downtime. The tanks and impacted soils above state cleanup……

-

UST Remediation AS/SVE System

Denver Metro Area, Colorado An air sparge/soil vapor extraction (AS/SVE) remediation system was designed based on pilot test data. A total of 6 AS wells and 5 SVE wells were to remediate gasoline constituents in the groundwater by directly volatilizing the constituents and supplying oxygen for aerobic biodegradation. The work included preparation of construction plans,……

-

UST Remediation LNAPL Multiphase System

Denver Metro Area, Colorado A multiphase extraction system was designed to address an extensive LNAPL plume spanning multiple off-site properties to dewater the upper low-permeability zone and allow product recovery and vapor extraction in the sand units where the NAPL was trapped. Based on extensive aquifer testing and site characterization, a system of six dual……

Plans, Permits, Compliance Projects

-

Flare Management Plan for NSPS Subpart Ja

Texas Refinery Prepared a FMP to comply with the final Standards of Performance for Petroleum Refineries (NSPS Subpart Ja). The plan provides the specifications of the flare system, documents applicability with the requirements of the regulation and outlines a compliance strategy, and included devising the best compliance strategy, calculating a baseline flare flow rate, drafting……

-

404 Permitting for Corrective Action Project

Wyoming Refinery Prepare a 404 permit application to reroute an intermittent stream that was in the location of a proposed corrective measure. The permit consists of a Pre-Construction Notification and includes wetland delineation, identification of an area for wetland mitigation and preparation of a Wetland Mitigation Plan. Endangered and threatened species, and historic properties listed……

-

Air and Land Use Permitting

Colorado E&P Waste Management Facility Prepared state and county major impact land use permit applications for a centralized E&P waste management facility, including: facility operations and contingency plans, storm water management, hydrology, geologic hazards, a sensitive area analysis with wildlife impact/habitat BMPs, land suitability and impact analysis, and property owner notifications. Analyzed potential air emissions……

-

Underground Injection Control Permit

Wyoming Refinery Obtained an Underground Injection Control (UIC), Class V, Beneficial Use Permit to support bio-augmentation using periodic microbe batch injections.

-

Spill Prevention Control and Countermeasure Plans

Colorado, Wyoming, Oklahoma and Texas Refineries Evaluated each facility for applicability and performed a gap analysis on existing plans. Used site-specific observations, measurements, maps and other documentation to address SPCC requirements. Planning distances were calculated and documented. Inspection forms, procedures and response plans were prepared based upon facility practices. SPCC plans were written to meet……

-

Refinery Oily Water Sewer Mapping

Texas Refinery Rule worked with refinery Engineering, Operations, Maintenance and Environmental Departments to create a comprehensive set of underground oily water sewer maps. Flow tests using dye and volume were extensively used to document connections. Dry weather flow contributors were identified. Individual drain systems were precisely located and placed into the refinery CADD system. QQQ……

-

Facility Response and Integrated Contingency Plans

Wyoming and Texas Refineries Emergency response plans were written to address specific regulatory requirements under 40 CFR §112.20. Care was taken to use facility practices and procedures where possible; recommendations for satisfying data gaps were made and follow-up work completed.

-

GHG Monitoring Plan and Emissions Inventory

Texas Refinery Gathered data from existing refinery fuel gas flow meters and CO2 CEMS, set up a calibration schedule, drafted a Green House Gas (GHG) Monitoring Plan and prepared and submitted the annual emissions inventory. The work was completed in compliance with the Green House Gas Reporting Program (40 CFR Part 98).